10 Different Types of Bricks Used for Indian Construction: A Comprehensive Guide

India has a rich history of brick construction, with the use of bricks dating back thousands of years. Bricks continue to be a popular building material in India due to their durability, affordability, and versatility. With advancements in technology and the introduction of new materials, there are now various types of bricks available for construction purposes. In this blog, we will explore ten different types of bricks commonly used in Indian construction. From traditional clay bricks to innovative alternatives, we will delve into their unique features, benefits, and recommended applications, providing valuable insights for anyone involved in the Indian construction industry.

Traditional Clay Bricks

Traditional clay bricks are the most widely used type of bricks in India. They are made by molding clay and firing it in kilns. Clay traditional brick are known for their strength, durability, and thermal insulation properties. They come in different sizes, shapes, and colors, allowing for diverse architectural designs. These bricks are commonly used for load-bearing walls, foundations, and exterior walls.Fly Ash Bricks

Fly ash bricks are an eco-friendly alternative to traditional clay bricks. They are made from a combination of fly ash, cement, sand, and water. Fly ash, a byproduct of coal combustion, is abundantly available in India. Fly ash bricks offer excellent strength, thermal insulation, and resistance to moisture. They are cost-effective, lightweight, and reduce the overall environmental impact of construction. Fly ash bricks find applications in both load-bearing and non-load-bearing walls, as well as in the construction of houses, commercial buildings, and infrastructure projects.Concrete Bricks

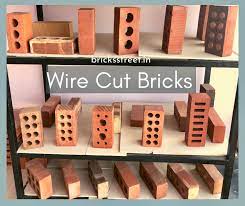

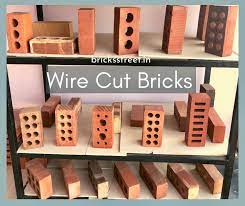

Concrete wire cut bricks are made from a mixture of cement, sand, and aggregates. They are known for their high compressive strength, durability, and resistance to fire and pests. Concrete bricks come in various sizes and shapes, allowing for flexibility in design. They are commonly used for load-bearing walls, retaining walls, and foundations.Hollow Bricks

Hollow bricks, also known as perforated bricks, have hollow cavities that reduce their weight and improve their thermal insulation properties. They are made by using molds with cavities or by extrusion. Hollow bricks offer good sound insulation and are commonly used in residential construction for both load-bearing and non-load-bearing walls.Cellular Lightweight Concrete (CLC) Bricks

Cellular Lightweight Concrete (CLC) bricks are made by incorporating foam into the concrete mixture. These bricks are lightweight, have excellent thermal insulation properties, and offer good sound absorption. CLC bricks are commonly used in the construction of low-rise buildings, partition walls, and infill walls.Sand Lime Bricks

Sand lime bricks, also known as calcium silicate bricks, are made by mixing sand, lime, and water. They undergo autoclaving to enhance their strength and durability. Sand lime bricks offer excellent thermal insulation and fire resistance. They are commonly used for load-bearing walls, external walls, and structures that require good thermal insulation.Perforated Bricks

Perforated bricks, as the name suggests, contain perforations or holes that extend through the length of the bricks. These holes enhance ventilation and moisture regulation, making them suitable for areas that require controlled airflow. Perforated bricks are commonly used in areas prone to high humidity, such as bathrooms, kitchens, and basements.Fire Bricks

Fire bricks, also known as refractory bricks, are specially designed to withstand high temperatures. They are made from heat-resistant materials, such as clay, silica, and alumina. Fire bricks are commonly used in fireplaces, kilns, furnaces, and other high-temperature applications.CSEB (Compressed Stabilized Earth Blocks)

CSEB, or Compressed Stabilized Earth Blocks, are made by compressing a mixture of soil, sand, and stabilizers like cement or lime. These blocks offer sustainability, as they utilize locally available soil and minimize the use of cement. CSEB blocks are commonly used in low-cost housing projects and rural constructions.Terracotta Bricks

Terracotta bricks are made from fired clay, giving them a distinctive reddish-brown color. They are known for their natural beauty and are commonly used for decorative purposes. Terracotta bricks can be used in both interior and exterior applications, adding a rustic and traditional touch to buildings.

Comments

Post a Comment